high efficiency wet ball mill

High Efficiency Ball Mill. High Efficiency Ball Mill Dry And Wet Mill Mackorn. The high efficiency ball mill is used to grind a variety of ores and other materials It acts as critical equipment for grinding .

WhatsApp)

WhatsApp)

High Efficiency Ball Mill. High Efficiency Ball Mill Dry And Wet Mill Mackorn. The high efficiency ball mill is used to grind a variety of ores and other materials It acts as critical equipment for grinding .

offers 1,044 clay milling machines products. About 12% of these are Mine Mill, 1% are Grinding Equipment. A wide variety of clay milling machines options are available to you, such as type.

The choice between wet and dry milling is, in general, unimportant in smallscale milling but is a major technical problem when largescale milling in the metallurgical industries is involved. On purely mechanical grounds it is difficult to see any great difference in fundamental principles between wet and dry milling, since dry milling may be regarded as wet milling with a fluid having the ...

RETSCH is the world leading manufacturer of laboratory ball mills and offers the perfect product for each application. The High Energy Ball Mill E max and MM 500 were developed for grinding with the highest energy input. The innovative design of both, the mills and the grinding jars, allows for continuous grinding .

Mar 03, 2015· Ball mill is an efficient tool for grinding many materials into fine powder. The Ball Mill is used to grind many kinds of mine and other materials, or to select the mine. It is widely used in ...

Grinding aids. Grinding aids have many different functions in the crushing of sample material. Grinding aids are particularly used with samples that have components with different grinding properties. The amount of grinding aid .

In this work, the effect of varying percentages of flotation additives and of oleonic acid on the wet milling of quartz and limestone, in a laboratory batch ball mill, was investigated. In each case the characteristic product particle size, d, resulting from grinding for 30 minutes was estimated from the .

The Mixer Mill MM 400 from RETSCH is a highperformance ball mill designed for grinding and homogenizing suspensions and powders within a few seconds, and achieving fineness down to the low micron range, thus making it a true versatile laboratory instrument. With two grinding stations, the MM 400 can concurrently prepare up to 20 samples.

Quartz and feldspar are the common rocks in mines. after being grinding by ball mill, quartz and feldspar are widely used in building materials. what should we pay attention to when choosing a ball mill? 1. the model. the ball mill can be divided into two kinds ball mills: dry grinding ball mill and wet grinding ball mill.

Effect of chemical additives on the dynamics of grinding media in wet ball mill grinding. International Journal of Mineral Processing 1985, 15 (4), 251267. DOI: /(85)900444. C. .

Ball Mill is a grinding device which is used to grind materials into fine powder with lining plate and grinding media inside the grinding drum, there are several kinds of ball mills: rod ball mill, batch ball mill, ceramic ball mill, Cement Ball Mill, and according to the working process, it can be divided into wet ball ball and dry ball mill, the wet ball mill .

Nov 16, 2016· This is a new product we are developing. It is a 3''x6'' continuous ball mill for small scale production at about 1 tph. This video shows walks through some of the basics of the ball mill, stay ...

RETSCH is the world leading manufacturer of laboratory ball mills and offers the perfect product for each application. The High Energy Ball Mill E max and MM 500 were developed for grinding with the highest energy input. The innovative design of both, the mills and the grinding jars, allows for continuous grinding down to the nano range in the shortest amount of time with only minor warming ...

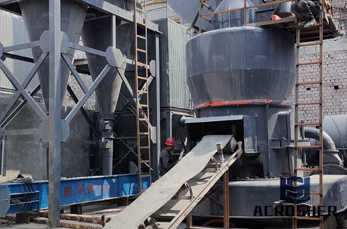

The ball mill is a key piece of equipment for grinding crushed materials, and it is widely used in production lines for powders such as cement, silicates, refractory material, fertilizer, glass ceramics, etc. as well as for ore dressing of ferrous and nonferrous metals. The ball mill can grind ores and other materials either wet or dry.

Quartz Powder Ball Mill, Quartz Powder Ball Mill Suppliers ... Alibaba offers 526 quartz powder ball mill products. About 69% of these are mine mill, 2% are grinding equipment, and 1% are other fabrication services. A wide variety of quartz powder ball mill options are available to you, such as ac motor, dc motor, and stepper motor.

ball mill with used in quartz grinding. Grinding kinetics of quartz and chlorite in wet ball milling slurry density was used. The small laboratory ball mill (Ø90mm 155 mm) used in this study limited us to use a maximum grinding ball size of 25 mm. Get Price; Ball Mill For Quartz Grinding Crusher Mills Cone

The polymerization of styrene mechanochemically initiated by the wet grinding of quartz was attempted by using a vibrating ball mill with a laboratory scale. The effect of the grinding of quartz on the polymerization of the styrene was investigated by characterizing the polymer formed and the quartz .

Ball mill grinder is usually used to grind crushed materials, such as ores, chemicals, ceramic raw material and others. This article mainly talks about ball mill for grinding calcium .

Feb 25, 2017· 143 quartz sand 30 minutes PULVERISETTE 6, dry grinding, 250 ml ZrO 2 bowl, 20 mm balls, average; 2 221 quartz sand 120 minutes PULVERISETTE 6, wet grinding, 2nd step, 250 ml ZrO 2 bowl, 320 g of mm ZrO 2 balls.

All Grinding Mill Ball Mill Manufacturers understand the object of the grinding process is a mechanical reduction in size of crushable material. Grinding can be undertaken in many ways. The most common way for high capacity industrial purposes is to use a tumbling charge of grinding media in a rotating cylinder or drum.

Jan 01, 2017· Laboratory batch wet ball milling tests of quartz and chlorite were carried out for four feed size fractions (− 2 + mm, − + mm, − + mm, + mm). The results showed that both quartz and chlorite demonstrated the firstorder breakage behavior in the feed size range investigated.

The Mixer Mill MM 400 from RETSCH is a highperformance ball mill designed for grinding and homogenizing suspensions and powders within a few seconds, and achieving fineness down to the low micron range, thus making it a true versatile laboratory instrument. With two grinding .

Quartz Powder Grinding Ball Mill Price. Quartz Powder Grinding Ball Mill To grind the crushed quartz sand to customer specified praticle size a ball mill is used The ball mill is essentially a rotating device with a horizontal orientation that moves by using the outer gear The quill shaft transfers the material to the grinding chamber uniformly Different types of steel balls are

So, selecting the efficient solution for grinding section is very important. Prominer provides ball mill / rod mill grinding system which is widely used in various types of ores'' beneficiation, electricity, cement and chemical industries. It can carry out dry or wet .

WhatsApp)

WhatsApp)