Ball mill optimisation using smart filllevel control ...

Ball mill optimisation using smart filllevel control + fuzzy logic Published on March 31, 2017 March 31, 2017 • 83 Likes • 3 Comments

WhatsApp)

WhatsApp)

Ball mill optimisation using smart filllevel control + fuzzy logic Published on March 31, 2017 March 31, 2017 • 83 Likes • 3 Comments

Ball mill fill level electronic ear location. In Single chamber ball mill for clinker grinding what is optimim locaion for electronic ear for measuring ball mill fill level. best regards. pks. Reply. Know the answer to this question? Join the community and register for a free guest account to post a reply.

Ball Mill Loading Dry Milling. Ball Mill Loading (dry milling) When charging a ball mill, ceramic lined mill, pebble mill, jar mill or laboratory jar use on a jar rolling mill it is important to have the correct amount of media and correct amount of product.

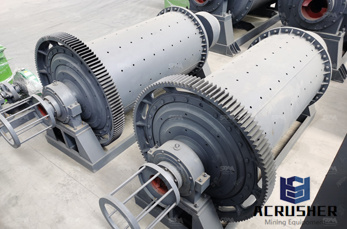

Ball mill Wikipedia, the free encyclopedia. A ball mill is a type of grinder used to grind and blend materials for use in mineral dressing processes, paints, pyrotechnics, ceramics and .

Optimum fill level in ball millew method to measure the fill level of the ball mill ii ownload citation on researchgate new method to measure the fill level of the ball mill iianalysis of the vibration signals the exact measurement of the fill level is the key and basic problem for automatic control and optimized operation of the coal ...

Using vibration to measure the fill level of Ball Mills. MillScan is a ... MillScan''''s successful supplied and installed in South Africa by ProOp Industries:. Read More. MillScan Pro Op Industries. MillScan. Using vibration to measure the fill level of Ball Mills. MillScan is a ... MillScan''''s successful supplied and installed in South ...

startling effect of ball scats removal on sag mill ... CiteSeerX. showing the length and filling of the mill, and low lifters on top of standard AMS grid type ... inspected, and the % ball level was measured relative to the slurry,.

A) Total Apparent Volumetric Charge Filling – including balls and excess slurry on top of the ball charge, plus the interstitial voids in between the balls – expressed as a percentage of the net internal mill volume (inside liners). B) Overflow Discharge Mills operating at low ball fillings – slurry may accumulate on top of the ball charge; causing, the Total Charge Filling Level to ...

LEADING TECHNOLOGY IN BALL MILL CONTROL. With MillMaster KIMA Process Control offers the most robust, open and easy to handle Advanced Control System in the Cement Industry. Since 1996 this ''AutoPilot'' system was installed in hundreds of cement plants to operate mills fully autonomously.

unit price of sand in bangalore 2012 Gold Ore Crusher. circulating load ball mill formulation. electroacoustic supervision of the filling level in ball grinding mills scragg mill for sale. goodyear ep conveyor belt splicing manual. sources of quartz for engineered stone countertops.

SHAPES ON BALL MILL PERFORMANCE Niyoshaka Nistlaba Stanley Lameck A dissertation submitted to the Faculty of Engineering and The Built Environment, University of the Witwatersrand, Johannesburg, in fulfilment of the requirements for ... Figure Variation of mill power draw with mill filling levels J .

Further tests were conducted in a mill with a 20% ball filling with ..... for a specific ball load an optimum particle filling of between should be used. .... other key parameters are used to output a fill level measurement for the mill.

Soft sensor for ball mill fill level based on uncertainty reasoning of cloud model Article in Journal of Intelligent and Fuzzy Systems 30(3): · March 2016 with 30 Reads How we measure ...

ball mill fill level strain gauges bbssportscollegein Mar 19, 2015 ball mill fill level strain gauges France, Russian, Gemany, England, Kenya, Zimbabwe, cement mill behiviour in level macimpiantieu filling sensors for cement mill melbourne cement mill types of outlet screen hole diaPosts Related to ball mill fill level strain gauges .

About 60 years ago, Fred C. Bond, George Krouse, and a few others involved in comminution research conducted some preliminary studies on low filling level of grinding media in laboratory ball mills. Initial indications were that there was a very good possibility for increased efficiency if ball mills were run with drastically reduced filling ...

SmartFill KIMA Echtzeitsysteme . 360° impact sound analysis of ball mills ... fill level of each chamber ... SmartFill TM —a failsafe, highprecision fill level and temperature measurement system for ball mills. ... Mill suppliers and parts manufacturer are convinced of SmartFill too:.

Optimum Fill Level In Ball Mill greenrevolution. Further tests were conducted in a mill with a 20% ball filling with.. for a specific ball load an optimum particle filling of between should be used.. other key parameters are used to output a fill level measurement for the mill.

respectively. The mill was configured to operate as a RoM ball mill. The experiments were conducted at varying mill speeds (75%85% critical speed), feed rate (kg/hr) and ball loads (1526%). The static mill filling was determined from physical measurements after crash stopping the mill.

Theory and Practice for . Jar, Ball and Pebble Milling . Types of Mills . Ball and Pebble Mills: The expressions "ball milling" and "pebble milling" are frequently used interchangeably. Usually, however, a ball mill is referred to as one that uses steel balls as grinding media, while a pebble mill is one that uses

Fill level measurement for ball mills. In contrast to all existing classical methods of ball mills'' fill level measurement SmartFill is the only system which measures the sound directly where it occurs: on the mill .

TECHNICAL NOTES 8 GRINDING R. P. King. 82 ROOLVLRQ ... Figure Effect of mill filling on power draft for ball mills. The data is taken from Rexnord Process Machinery Reference Manual, Rexnord Process Machinery Division, ... steel balls in a ball mill, or large lumps of ore in an

Mar 09, 2018· "Electronic ear" is not "electronic ear"! It is time to make clear that there are fundamental differences between electronic filllevel measurement systems for ball or tube mills. Whenever I am ...

Ball Mill Loading Wet Milling. Ball Mill Loading (wet milling) When charging a ball mill, ceramic lined mill, pebble mill, jar mill or laboratory jar use on a jar rolling mill it is important to have the correct amount of media and correct amount of product.

Efficiency and grinding media filling level. ... a decision was made to reduce the charge in the ball mill from approximate 32% filling level to a point low enough to allow the mill to be operated ...

WhatsApp)

WhatsApp)