Tools for Micro and Nano Research Search – MicroNanoTools

MicroNano Tools designs, develops, manufactures, and sells laboratory equipments, especially in the fields concerning micro and nano technology.

WhatsApp)

WhatsApp)

MicroNano Tools designs, develops, manufactures, and sells laboratory equipments, especially in the fields concerning micro and nano technology.

RSG Inc, located in Sylacauga, Alabama specializes in fine powder technology. The company manufactures air classifiers, ball mills and stirred media mills for the production of fine, superfine and ultrafine powders for the mineral, mining, cement, lime, metal powder and chemical industries.

Planetary Mills are ideally suited for fine grinding of hard, mediumhard, soft, brittle, tough and moist materials. The comminution of the material to be ground takes place primarily through the highenergy impact of grinding balls in rotating grinding bowls.

About product and suppliers: offers 6,815 nano mill products. About 54% of these are milling cutter, 33% are grinding equipment, and 4% are mine mill. A wide variety of nano mill options are available to you, such as free samples, paid samples. There are 6,795 nano mill suppliers.

30 Innes Road (cnr Graniet Rd), Jet Park Ext. 66 Boksburg, Gauteng South Africa

We are leading manufacturer and supplier of Planetary Mill (Era), Planetary Mill (Auriga), Nanocrystalline Iron Carbide, Glove Box, Compaction Die, Planetary Ball Mill, Laboratory Ball Mill, Particle Size Analyzer, Hydraulic Compaction Press, Ultrasonic Bath, High Temperature Muffle Furnace, Fume Hood etc. Also offering consultancy services.

Jinan Zhongwei Casting And Forging Grinding Ball Co.,Ltd have been specialized in Grinding Steel Ball manufacture for many main products are various kinds of Forged Steel Ball,Mill including Cast Iron Ball,etc.

Current market is still using between 1~20 micron particles for MRF. ABM Nano innovated manufacturing process making Nanosized Iron Particles which is a groundbreaking achievement. The MR Fluid quality exceeds any suppliers in the field. Please feel free to contact us for any inquiries.

Specifications of laboratory ball mills include 12 in. x 12 in. cast iron drum size, 285 ball charge, one to two phase, 110 to 440 V voltage, cycles in the range of fifty to sixty lbs. iron ball charge weight. Ball mills are available with iron stands, receiving hand screen pans digital counters.

Jun 15, 2012· Steps in ball milling method; 1. As the name suggests, the ball milling method consists of balls and a mill chamber. Therefore over all a ball mill contains a stainless steel container and many small iron, hardened steel, silicon carbide, or tungsten carbide balls are made to rotate inside a mill .

The 21 Liter (5 gallon) 911METALLURGY 911MPE21BM dual function Laboratory Rod Mill / Ball Mill is designed to meet the industrial requirements to grind coal, cement and a wide variety of ores. The dual duty Laboratory Grinding Mill consists of a gear motor mounted on a high precision solid steel underframe complete with outlet funnel and a set of separation screens plus sample collector.

In our agitator bead mills program you will find the best solution for both batch, as well as continuous operation, whether for the dispersing of agglomerated product suspensions or the disaggregation of your products to energetically introduce real comminution to the nanometer range. Real comminution and dispersing with NETZSCH agitator bead mills

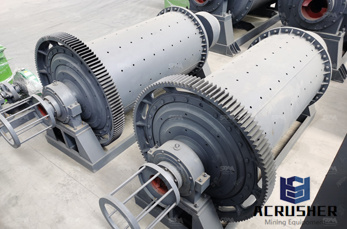

New and Used Ball Mills for Sale Savona Equipment is a new and used Ball Mill supplier ball mill is a type of grinder used to grind materials into extremely fine powder for use in mineral dressing processes, paints, pyrotechnics, ceramics and selective laser sintering.

Planetary Ball Mill; Dual Planetary Ball Mill Cryogenic Planetary Ball Mill Vertical Planetary Ball Mill for Glove Box Use Heavyduty Fulldirectional Planetary Ball Mill Laboratory FullDirectional Planetary Ball Mill Laboratory Horizontal Planetary Ball Mill Mini Vertical Planetary Ball Mill Heavyduty Horizontal Planetary Ball Mill Vertical ...

The E max is an entirely new type of ball mill for high energy milling. The unique combination of high friction and impact results in extremely fine particles within the shortest amount of time. faster and finer grinding than any other ball mill; speed of 2000 min1 allow for ultrafast pulverization of the sample

Zirconia (YSZ) grinding media is the most durable and efficient media for ball milling and attrition milling of ceramic materials. Zirconia grinding media provides a virtually contaminationfree ball milling solution for a variety of industries.

Comminution processes using laboratory batch planetary ball mills have been reported by many authors for iron oxide and other minerals (Chen et al., 2007, Sanchez et al., 2004, Sanshez et al., 2007). However, little attention has been paid to the occurrence of the mechanochemical effect in the fine grinding periods.

now Offers End Mills Smaller than .001" Through literally thousands of hours of research and development, Performance Micro Tool has been able to manufacture end mills as small as 5 microns in diameter. Today, we offer a line of nanosized tools from 5 to 400 microns in diameter.

Jul 26, 2017· Making aluminum powder with only some aluminum foil, the ball mill jar we built last video, and some steel balls! Perfect for use with thermite, tannerite, or flash powder, this process will ...

Manufacturer of balls includes ball mill balls. Specifications of ball mills include 12 in. x 12 in. cast iron drum size, 285 ball charge, one to two phase, 110 to 440 V voltage, cycles in the range of fifty to sixty lbs. iron ball charge weight. Ball mills are available with iron stands, receiving hand screen pans digital counters.

Synthesis, characterization and application of zero valent iron ... The particle size of iron nano particles ranged from tens to hundreds of nanometers (Sun et al. 2007). ... These were ground in a ball mill such that the material

The High Energy Ball Mill E max and MM 500 were developed for grinding with the highest energy input. The innovative design of both, the mills and the grinding jars, allows for continuous grinding down to the nano range in the shortest amount of time with only minor warming effects. These ball mills are also suitable for mechano chemistry.

Performance Micro Tool manufacturers Micro and Miniature End Mills, Drills, and Routers for high performance machining. Sizes range from .0002 up to .125

Apr 03, 2013· This article looks at grinding down to the nanoscale with planetary ball mills. This article looks at grinding down to the nanoscale with planetary ball mills. ... Figure 3 shows the sample of aluminium oxide ground to particles in the nano range. ... Fritsch is one of the internationally leading manufacturers of application oriented ...

WhatsApp)

WhatsApp)