THE MAKING(English Version) (314)The Making of Steel Balls

Nov 11, 2015· Extreme Dangerous Biggest Heavy Duty Hammer Forging Factory, Hydraulic Steel Forging Process Duration: 14:02. Good Machine 5,257,616 views

WhatsApp)

WhatsApp)

Nov 11, 2015· Extreme Dangerous Biggest Heavy Duty Hammer Forging Factory, Hydraulic Steel Forging Process Duration: 14:02. Good Machine 5,257,616 views

These ball materials are often used because they are inexpensive. Nylon is one of the most common plastic ball materials. It is hard, it is tough and it is dense enough so that it sinks in water. Nylon is slightly hygroscopic, so it isn''t the best plastic to be used in water applications. PTFE. is a fairly common plastic ball material.

Balls 4 The balls are a little more difficult to make, even though their shape is very simple. Surprisingly, the balls start out as thick wire. This wire is fed from a roll into a machine that cuts off a short piece, and then smashes both ends in toward the middle. This process is called cold heading.

Oct 23, 2012· Trials realized in our workshop for checking the maximum speed of our small cotton balls machine PM4.

Do you want an ice ball maker like those sold online, but don''t have 800+ to spend? Then make your own! Don''t know what an ice ball maker is, or how it works? Then check out the last page of this Instructable for a video of it in action. You''ll need access to a machine shop, and specifically a CNC machine.

That ball has since been replaced by a textured tungsten carbide ball. This material is superior because it is particularly resistant to deforming. The ball is designed to be a perfect sphere that can literally grip most any writing surface. Its surface is actually composed of over 50,000 polished surfaces and pits.

Machining is a process in which material is removed from a workpiece to shape or finish it into a desired form. Drilling, holemaking, milling, turning, and threading tools are attached to compatible machinery such as a lathes, drill presses, or CNC machines to perform machining operations on the workpiece.

Mar 28, 2017· Ball bearings are rolling element bearings that use balls to separate the bearing races and provide smooth, low friction motion in rotary applications. Ball bearings are manufactured in hundreds of sizes, from the ultrasmall mm diameter bearing for use with miniaturized medical devices and micromotors, to bearings over 15 feet in diameter for use in heavy equipment.

Holes are by far the most common feature in CNC machining. The material removal rate of twist drills is outstanding, and usually better than equivalent sized end mills. Twist drills come in many more diameters and sizes than end mills. It often makes sense to drill the ends of a slot and then machine out the web between the holes with an end mill.

Jul 10, 2012· I have to machine a trailer hitch type ball and am very unfamiliar with using i and k values for radii. I intend to do it in two halves, the front half using an r value and a right hand turning tool then groove out the back site and finish it with a left hand tool in a +z direction.

A homemade skee ball machine intrigued me as a challenging project. After a little research I became discouraged by the ''electronic scoring'' aspect. The few who have attempted to make a Skee Ball Machine with an actual realistic electronic scoring panel, have often been met with crashes, burn outs and the big expense of replacing circuit boards.

Machining is a term used to describe a variety of material removal processes in which a cutting tool removes unwanted material from a workpiece to produce the desired shape. The workpiece is typically cut from a larger piece of stock, which is available in a variety of standard shapes, such as flat sheets, solid bars, hollow tubes, and shaped beams.

Apr 23, 2020· Create a skee ball game similar to one described on the Momtastic site. Make a ramp by cutting the short side of one of the boxes so it lies down flat. Be sure to leave the rest of the box intact. You should have a box that is solid on three sides with a flap that folds out.

Jan 21, 2014· NC 31 Ball Valve Machining Center SPM Duration: 1:19. _Axisco Precision 11,069 views. 1:19. Radius Ball Turner for Metal Lathe Duration: 8:28.

Therefor it''s hard to machine. We have published a complete guide to machining tungsten, so be sure to refer to it before you try to work with this material. Uses: About half of all tungsten production is used to manufacture cutters of various kinds. Most of the rest involves using tungsten to make .

The OMW RadiusBall Turning Tool is designed to cut convex radii (ball shapes) on a variety of materials. Using the tool, you can make ornamental balls on the end of handles, ball joints, governor weights, round contact points for tools, nose cones, and many other useful and decorative objects. The OMW Radius tool is sized for small to medium sized

The large balls tend to break down the coarse feed materials and the smaller balls help to form fine product by reducing void spaces between the balls. Ball mills grind material by impact and attrition. The degree of milling in a ball mill is influenced by; a. Residence time of the material in the mill chamber. b. The size, density, and number ...

The sheets are fed through a press that applies a latex adhesive and attaches the cloth. Material for a cheaper ball will receive a twolayer backing. ... Manufacturers hope to improve the stitching technology so that all grades of balls can be made by machine in the future. ... Therefore one cannot make a soccer ball with 32 hexagonal faces ...

Make sure this fits by entering your model number.; The Whiskey Ice Co. (66 mm) Original Spherical Ice Ball Maker marries science and design to perfectly chill your beverage of choice, with less dilution, when compared to regular square ice cubes.

Jun 19, 2018· High Efficiency Milling. High Efficiency Milling can be a very effective machining technique in stainless steels if the correct tools are selected. Chipbreaker roughers would make an excellent choice, in either 5 or 7 flute styles, while standard 57 flute, variable pitch end mills can also perform well in HEM toolpaths.. HEV5. Helical Solutions offers the HEV5 end mill, which is an ...

I make sure that I order all the items for one machine at the same time so that I only pay postage once. So lets have a look at some of the mechanisms. I will just include the ones that are used on the Alice machine. Pop bumpers, Flippers, Shooter, and Ball Return.

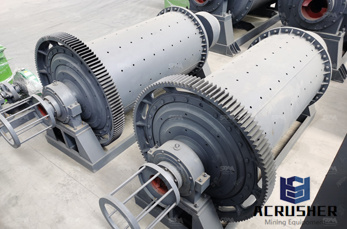

A ball mill, a type of grinder, is a cylindrical device used in grinding (or mixing) materials like ores, chemicals, ceramic raw materials and mills rotate around a horizontal axis, partially filled with the material to be ground plus the grinding medium. Different materials are used as media, including ceramic balls, flint pebbles, and stainless steel balls.

Our quickturn CNC Machining can ship 1 to 200 parts in 1 to 3 days. With over 30 plastic and metal machining materials and hundreds of highspeed CNC machines, we make your enduse parts quickly helping you stay ead of schedule. Request your free quote and design analysis now.

Make a Marble Machines Board: A Marble Machine is a creative ballrun contraption, made from familiar materials, designed to send a rolling marble through tubes and funnels, across tracks and bumpers, and into a catch at the end. In this activity guide, you''ll learn how to ...

WhatsApp)

WhatsApp)