mechanical engineering: Types of rolling mills

A four high rolling mill is used for the hot rolling of armor and other plates as well as cold rolling of plates, sheets and strips. 4: Tandem rolling mills: It is a set of two or three stands of roll .

WhatsApp)

WhatsApp)

A four high rolling mill is used for the hot rolling of armor and other plates as well as cold rolling of plates, sheets and strips. 4: Tandem rolling mills: It is a set of two or three stands of roll .

Fourroller mills Fourroller mills have two sets of rollers. When using a fourroller mill to mill grain, the grain first goes through rollers with a rather wide gap, which separates the seed from the husk without much damage to the husk, but leaves large grits.

Jun 28, 2017· The Three Roller Mill is made up of a machine base, cover, roller bearing, Teflon endplates, discharge collecting blade, cooling system, gears, and wheels. There is a total of six bearing bases ...

Oct 21, 2011· triple roll mill ashokshastri8119. Loading... Unsubscribe from ashokshastri8119? ... JH Day Heavy Duty 3Roll Hydraulic Dispersion Mill Demonstration Duration: 4:44.

Best practices for safe and efficient three roll milling Theory of operation . A three roll mill is composed of three horizontally positioned rolls rotating in opposite directions and at different speeds. The material to be milled is placed between the feed and center rolls and gets transferred from the center roll to the apron roll by adhesion.

Is a three roll mill needed in your application? Are you ready to move forward and invest in a three roll mill? With years of experience manufacturing three roll mills and serving customers over 30 countries, we understand your first priority is to determine how much to budget for a three roll mill.

The draft attempted in this rolling operation is d = 25 22 = 3mm From equation () we can find the maximum draft d max = () 2(250) = Since the maximum allowable draft exceeds the attempted reduction, the rolling operation is feasible. To compute rolling force, we need the contact length L and the average flow stress Yf .

In hot rolling mills, premature failure of rolls is a major concern as it adversely affects the mill operation as well as production. Analysis of failed roll materials and actual rolling conditions in service are therefore necessary to understand the roll failure mechanism and thereby improve the wear resistance and extend the service life of rolls.

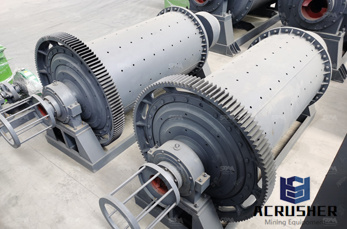

A mill is a device that breaks solid materials into smaller pieces by grinding, crushing, or cutting. Such comminution is an important unit operation in many are many different types of mills and many types of materials processed in them. Historically mills were powered by hand (, via a hand crank), working animal (, horse mill), wind or water ().

Jan 10, 2018· 3 Roll Bending Machine (Working Principle and Rolling Process) Home > Rolling > 3 Roll Bending Machine (Working Principle and Rolling Process) Table of Contents. Learn More About OurPlate Roll Bending Machine. 3 Roll Bending Machine Working Principle ... convenient operation and low cost. As for the problem of eliminating the straightline ...

Monster Brewing Hardware Monster Mill MM 2/3/PRO Instructions MM2 MM3 MM2PRO MM3 PRO Congratulations on your purchase of one of the finest home brewery grain mills available. This mill is designed for a lifetime of use, easy operation, and .

Operation 1. Be sure to acquire all required training before operating the roller mill. Operation requires sitespecific training on this machine. 2. Be sure to wear all required personal protective equipment (listed in Figure 1) before operating the roller mill. 3. Be sure to familiarize yourself with the operation of this machine prior to ...

Jun 06, 2012· This Three Roll Mill lab model offers faster roller speeds and higher throughput up to gallons or 30 pounds per hour. The fast roller runs at 432 RPM. Variable frequency drive allows ...

Three Roll Mills . A three roll mill is a machine tool that uses the shear force created by three horizontally positioned rolls rotating at opposite directions and different speeds relative to each other to mix, refine, disperse, or homogenize viscous materials fed into it. They are widely used to mix electronic thick film inks, high performance ceramics, cosmetics, plastisols, carbon/graphite ...

Jun 12, 2014· A new safety training video for three roll mill operation is now available for sale from NAPIM. This safety training video was produced by the National Association of Ink Manufacturers'' Health and Safety Committee. It was developed following the requirements of ANSI Standard B65/NAPIM Safe Operation – Ink Three Roll Mills.

Powerful gears in rolling mills | Machine Design. After many years of service, the gears in a hotstrip rolling mill must be replaced. ... and spalling, as well as cracking in tooth areas, Figure 3, and in gear blanks. ... of the mill operation applied in combination with experience in designing large...

3roller modular Loesche mill Type LM D in Kosice, Slovakia, 1991 The modular structure of larger roller grinding mills enables utilisation of the same components in different mill sizes. Module components include grinding rollers, rocker arms, pedestals and spring assemblies. The principle behind this structure was patented in 1970 and

A Three Roll Mill has three horizontally positioned rollers. Each roller rotates in an opposite direction from the adjacent roller with a tiny gap between them, creating tremendous shear force that can finely disperse, mix, refine or homogenize viscous materials.

3 / 5 Roller Mill for Mineral / Ore Grinding. ... The grinding operation in Singhasini 3 / 5 Roller Mill is performed on the principle of attrition and ... Technical Specification... Get Price. MPS vertical roller mill Gebr. Pfeiffer. The versatile MPS vertical mill – with a fine tradition of .

A Three Roll Mill (Three Roll Mill 101) has three horizontally positioned roller rotates in an opposite direction from the adjacent roller with a tiny gap between them, creating tremendous shear force that can finely disperse, mix, refine or homogenize viscous materials.

The power used to operate SvenMill roller mills is far less than a PTO tractor. An average cost of an electric motor powered mill is approximately an hour versus approximately an hour for a PTO drive off a modern tractor.

After a roll change or a mill stop rolls need some time to return to stable thermal conditions, every new bar entering the mill creates an impact, ... and sometimes there are really severe rolling accidents, due to faults by operators, weak rolled materials with internal defects, or because

The Williams Roller Mills are designed to provide years of reliable, consistent, and efficient operation, but the reason why Williams is one of the leading roller mill manufacturers is their ease of use and maintenance. Learn more about the features of the Williams roller mill crushers to see why they should be your top choice.

Roll forming, roll bending or plate rolling is a continuous bending operation in which a long strip of metal (typically coiled steel) is passed through consecutive sets of rolls, or stands, each performing only an incremental part of the bend, until the desired crosssection profile is obtained. ... A rolling mill, also known as a reduction ...

WhatsApp)

WhatsApp)